Kirsty McGhie

Architect

Passive House Designer

Lancaster Passive House

" In 2022 I was very fortunate to be asked to design a low energy, low carbon house for someone who was prepared to build their own home. This article is written to explain the design of a Passive House, to describe the construction approach used and to highlight the advantages of the certification process. "

Kirsty McGhie

Certified Passive House Plus

How we did it....

1. The Brief

James and Debbie Glass wanted to downsize from their three storey townhouse to a more economical and more sustainable new home. They asked JMP Architects in Lancaster to design a three bedroom, adaptable, low energy family home, to be built using natural materials.

2. The Site

The site is a corner plot, only 1 mile from the city centre, south facing, away from large trees and is adjacent to existing services.

The land had previously been part of a domestic garden, containing a greenhouse, a shed and a number of small trees. Bounded by timber fencing, there was also an overgrown Leylandii hedge along the southern boundary. The ground slopes from the north-east corner to the south-west corner, where the garden meets the back of the public footpath.

As JMP's in-house Passive House Designer, Kirsty was asked to look at the design.

The brief was to design a home which was energy efficient, easy to use, comfortable, accessible and adaptable. Aiming for the Passive House Standard was the perfect solution to achieve what James and Debbie wanted.

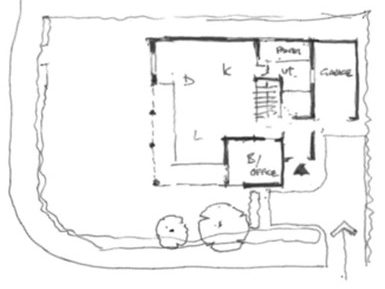

3. The Concept Design

Kirsty organised the layout of the living room and bedrooms to face south, to capture the warmth of the sun. The kitchen, utility and boot room are laid out across the rear, north facing elevation. A study, or future fourth bedroom, is located on the ground floor adjacent to a spacious shower room.

It was important that the main entrance should face the main road, adjacent to the driveway.

4. The Design process

Once the general layout was agreed, the proposed building, the site, and the neighbouring property was modelled in "SketchUp". This allows us to look at how the sun hits the building at different times of the day throughout year.

Kirsty then used the SketchUp pluggin "designPH", to calculate the anticipated energy use of the house.

designPH was developed by the Passive House Institute to provide an interface between a SketchUp 3D model and the Passive House Planning Package (PHPP). The 3D model will calculate the annual space heating demand for the proposed building, which is measured in kWh/(m2a): kilowatt-hours per meter squared per year.

The envelope of the building, the window area and the floor area are measured by the designPH tool. Taking into account the orientation of the windows, it can calculate how much energy will be required to heat the building throughout the year. This is referred to as Space Heating Demand.

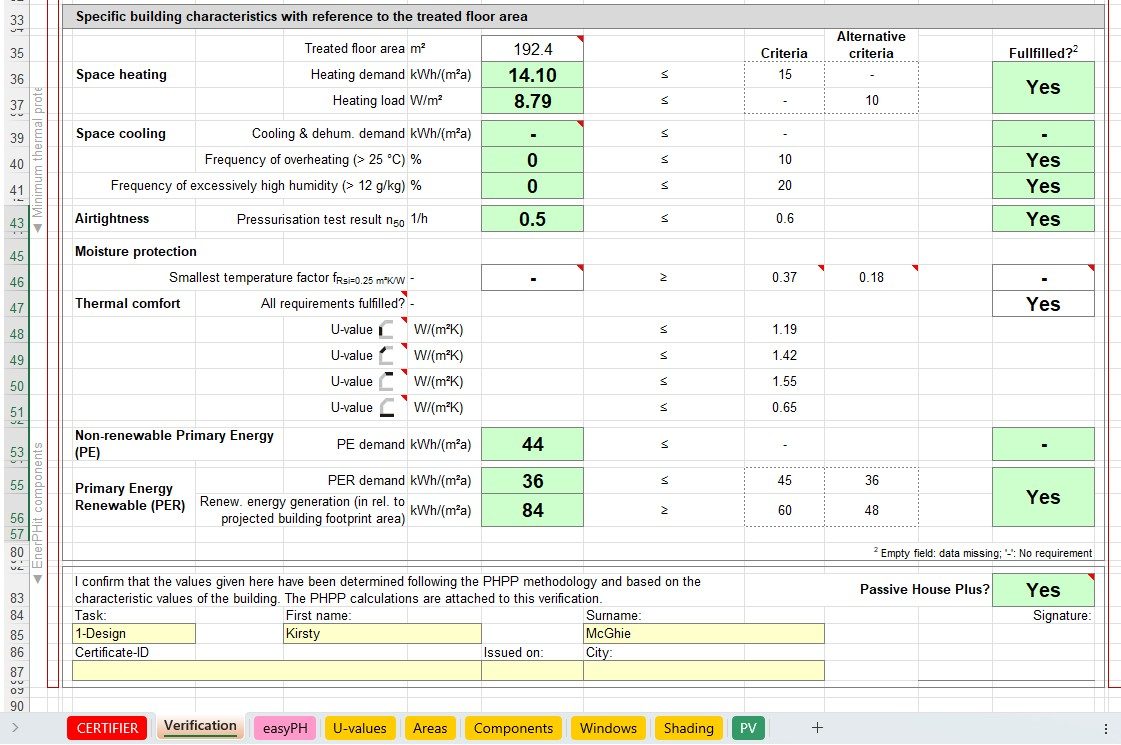

The designPH model was then exported to the Passive House Planning Package (PHPP) which is an Excel document. The more information which is added to the PHPP, the more accurate the Space Heating Demand calculation will be.

The PHPP requires information input on: Climate, fabric U-values, Areas of external envelope, Components (window frames, glazing, MVHR), Window size and orientation, Shading, Ventilation, Heating, Summer Ventilation, Domestic Hot Water, DHW distribution, Photovoltaic systems, Electrical appliances, Primary Energy generation (PER), and the Heat Pump.

As this project is a single dwelling, Kirsty was able to use the simplier version of the PHPP, "easyPH".

Once the shape and form of the building has been shown to achieve a Space Heating Demand of less than 15 kWh/m2a), the design is developed further. We look at the window and door arrangement and the external materials. At this stage we are working towards making a Planning application but still using the designPH to check the Space Heating Demand will achieve Passive House standard.

5. Materials

A priority for James and Debbie was that the building should be low energy and include natural materials, with minimal embodied energy, where possible.

Firstly, we decided that the structure should be timber frame. We looked at a number of different timber frame systems but decided that an I-beam was the best solution as it has less timber than a standard timber stud. The structural timber parts are smaller, and the thin web of the beam reduces the thermal bridge from outside to inside. James and Debbie visited the PYC Construction factory in Mid Wales and saw how the insulated panels are constructed. They then visited the BUILD-A-KIT factory in Nelson, Lancashire, where Bill Richardson has developed a panel system for low-energy and Passivhaus buildings, using mineral wool insulation between 300mm deep timber I-beams.

The advantage of using a natural material like Rockwool mineral wool is that it creates a breathable construction. It has great thermally insulating properties, it is inherently fire resistant, it is an acoustic insulation, but it is also vapour permeable. The BUILD-A-KIT panels have factory fitted Pro Clima Intello Plus vapour control membrane on the inside of both the wall and roof panels.

Intello Plus vapour control membrane is a climate-controlled membrane. The fleece membrane provides a seal against moisture in winter, but in summer, the molecular structure becomes more open to allow drying to the inside. This protects the timber structure from moisture damage or mould growth within the panels.

The outside of the BUILD-A-KIT panels are clad with Panelvent board and covered with a breathable membrane. Panelvent is a structural fibreboard, used as a sheathing board, which is also vapour permeable. The boards have a natural wax additive so, in certain circumstances an additional breather membrane is not required. As James and Debbie wanted timber cladding as an external finish, which will act as a rainscreen, the additional breather membrane was required.

Preferring to use natural materials as much as possible, James and Debbie looked at different timbers for the external cladding. After seeing a timber clad house, they decided on Cedar. The natural oils in Cedar make it resistant to rot and insect damage. It is low maintenance and will shrink and swell less than other timbers. When left untreated, Cedar will gradually weather to a silver grey colour.

The windows and doors are all timber. After visiting a house building exhibition, James and Debbie met Mike Shufflebotham from 21 degrees, formally Green Building Store. 21 degrees manufacture a range of triple glazed, air tight windows for Passivhaus projects. Timber windows have a lower carbon footprint than alu-clad windows. They can last for decades when properly maintained. They can be easily refurbished or repaired to extend their lifespan and reduce the need for replacement. Lancaster Passive House windows are finished in a mid grey colour which will sit well with the Cedar cladding as it weathers.

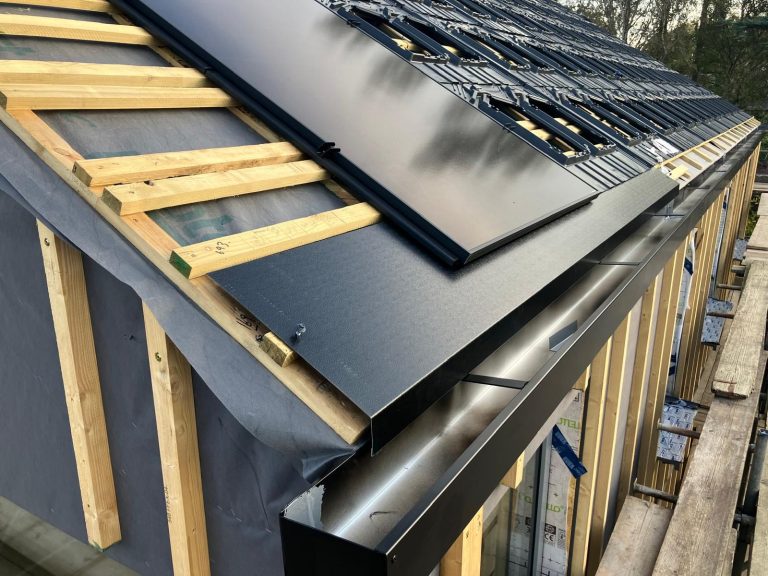

As this is a low energy house, James and Debbie wanted to include Photovoltaic (PV) panels on the roof. James didn't want just a patch of PV panels surrounded by slate. The roof had to look uniform, so it was decided to cover the the south facing roof with as many panels as possible. The panels sit within a perimeter metal edge, which is powder coated to match the ridge capping and the gutter.

The rear, north facing roof is cover by a blanket of Sedum. The "Riefa Green Roofing" system was provided by Paul Gilby from nearby Halton. Sedum requires very little maintenance but as the roof slope is 30 degrees, the water tends to run off quite quickly. A water irrigation system under the Sedum makes sure it can be evenly watered after a long dry spell.

Inside, James and Debbie have continued to use natural materials. The majority of the ground floor has engineered Oak flooring over insulated underfloor heating boards. The stair and balustrading, manufactured and fitted by Mike Jackson of MDJ Staircases Ltd, are solid Oak.

1. BUILD-A-KIT timber panels. 2. Cedar timber cladding. 3. Photovoltaic panels to the south facing roof. 4. The green roof is Sedum. 5. Timber windows and doors. 6. The stair and timber flooring are Oak.

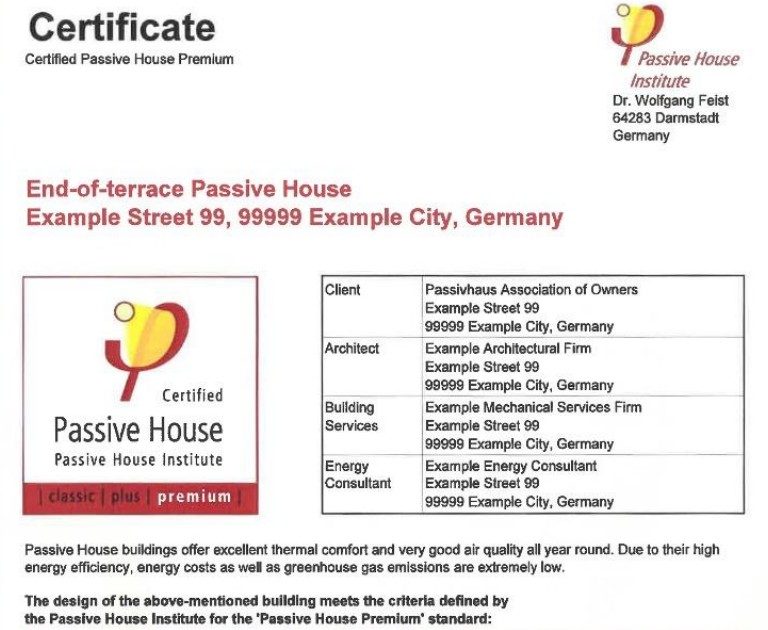

6. Certification

Every Passive House should be Certified by a Passive House Institute accredited Certifier, to ensure it meets all the criteria of the Passive House standard.

As soon as James and Debbie obtained Planning Permission for Lancaster Passive House, they were keen to make a start on site. Firstly Kirsty had to make an application to Building Control. Secondly, as a self builder, James needed to find a structural warranty provider. Stroma Building Control partners with a number of different warranty providers so they can offer a Structural Warranty to their Building Control clients. Stroma were appointed as both the Building Control services provider and the Structural Warranty provider.

JMP Architects were appointed to act as Principal Designers for Building Regulations, to ensure that Lancaster Passive House is compliant with the regulations. As a self builder, James was responsible for ensuring the building was built as per the approved drawings and specification. The Building Regulations are not a quality standard. They are a minimum standard for health and safety in new buildings.

The Passive House Standard is an independant quality assurance standard provided by the Passive House Institute in Germany.

Achieving Passive House Certification means a building has been meticulously planned, executed, and tested to meet the highest performance standards. The certificate is only issued if the precisely defined criteria have been met without exception.

Kirsty obtained a couple of quotations for Passive House Certifier services and it was agreed to work with Zero Energy based in Manchester. Zero Energy set up an online certification platform. As the Passive House Designer, Kirsty uploaded all the information required to show compliance with the Passive House standard.

There was a lot of information required, including: - The completed PHPP, the designPH model, plans, cross sections, elevations, Treated Floor Area calculation, Internal air volume calculation, Shading objects, Insulation data sheets, Perimeter Thermal Bridge calculations, glazing data sheets, window frame data sheets, rooflight data sheets, window installation details, door details, rooflight details, MVHR design drawings, ductwork datasheets, ASHP technical information, hot water heat generator technical information, hot water distribution drawings, underfloor heating design drawings, drainage design, ventilation design, photovoltaic panels data sheets, inverter datasheet, air tightness test reports, ventilation commissioning reports, and site construction evidence photographs.

Zero Energy carried out a Preliminary review of the concept design information, a Design Stage review, which should ideally be before the works commence on site, and a Final Review after completion of the construction works.

7. Construction

Once site insurance was in place and the Building Control plan checks were complete, James made a start clearing the site. Darren Winning was brought in to carry out the ground works and form the retaining wall at the rear of the site.

Darren proved to be an invaluable member of the team. Winning Building Services stayed and worked on the ground floor construction, below ground drainage, the timber cladding, the rear roof waterproofing, the sedum roof installation, the internal wall linings, all the internal joinery & flooring, and all the external landscaping works.

The substructure cavity walls contain 150mm thick Recticel PIR insulation.

Recticel PIR insulation boards being laid over a damp proof membrane.

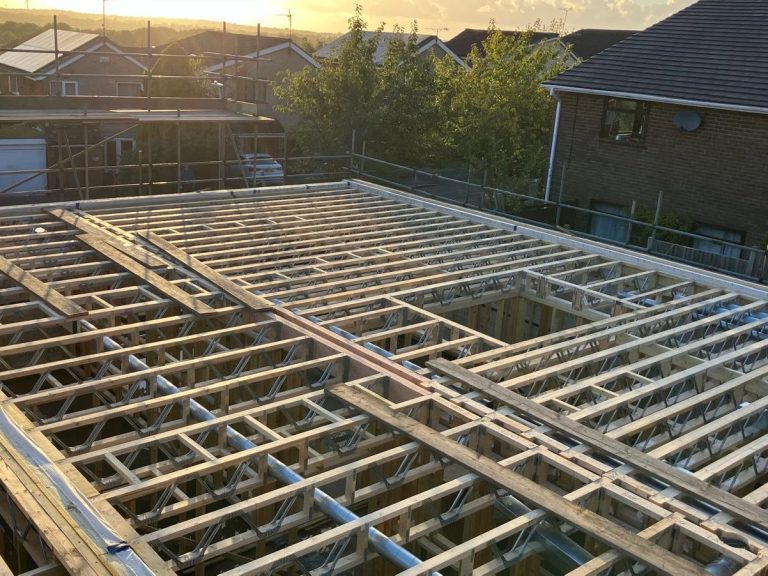

Erection of the BUILD-A-KIT timber frame panels.

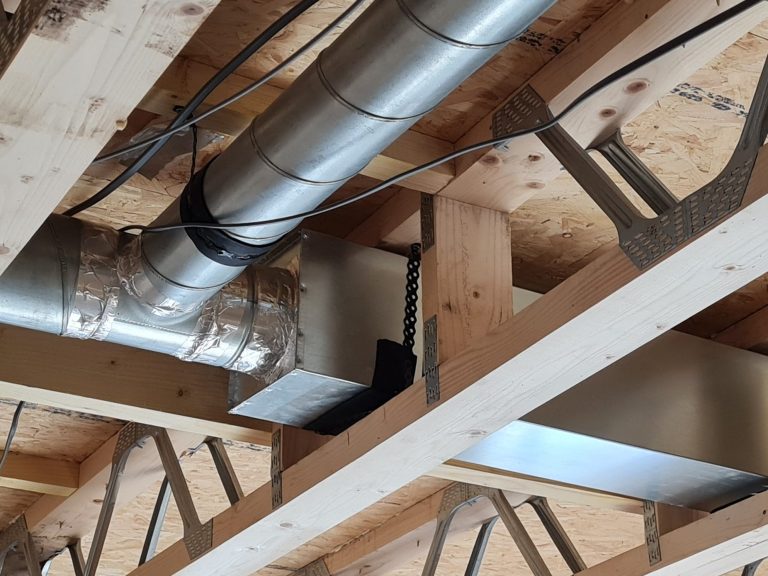

BUILD-A-KIT supplied and fitted metal web first floor joists to allow the ventilation ductwork to sit within the depth of the floor construction.

The rear roof is coated with a glass fibre waterproofing system by Winning Building Services.

The inside of the wall and roof panels have an Intello Plus breathable airtight membrane which is protected by a service void.

PV panels being fitted to the south facing roof

The Sedum blanket on the north facing roof, insatlled by Winning Building Services.

High performance triple glazed timber windows being installed.

High performance triple glazed timber windows and doors.

Cedar timber cladding to all four elevations, fitted by Winning Building Services.

MVHR ducwork installed within the first floor joists.

Underfloor heating pipes to the ground floor.

Diane Hubbard carrying out the initial air test.

Engineered Oak flooring fitted by Winning Building Services.

Oak skirtings and window reveals fitted by Winning Building Services.

Kitchen by Maelstrom Kitchens & Bathrooms

Bathrooms by Bathtime Northwest

Once the external envelope and the internal walls and floor have been installed, an intermediate air test is carried out. The new building is heated and then pressurised using a fan fitted into an opening window. Diane Hubbard from Green Footsteps Ltd, then calculated the airtightness of the building envelope.

A Passive House building must achieve an airtightness of 0.6 air changes per hour, or better.

It is useful to find, and then rectify, any holes in the airtighness membrane before the internal linings are installed. Diane used a thermal imagining camera to identify any leaks. Outside air being drawn into the building will be colder than the air in the heated interior.

These images taken by Diane, show cold spots where outside air has got into the external wall construction. James quickly found the holes and taped them up.

Passive House Certificaton also requires the external envelope to be Thermal Bridge free.

Lancaster Passive House has a cantilever over the main entrance door, which is supported by two steel beams located within the external timber frame walls at first floor level. Any steelwork with the external envelope will act as a Thermal Bridge. It was essential that all the steel was surrounded by high performance insulation. The effect of the insulation on the Thermal Bridge must be calculated. Kirsty used "Flixo" software to measure the Psi value and the internal temperature on the surface of the walls at the location of the steel beams.

8. Heating and Ventilation

As with the construction materials, James and Debbie wanted their new home to be energy efficient to reduce carbon emissions. James met with services engineer, Phil Metcalf. Phil Metcalf Ltd. Cooling and Heating Services, based in Lancaster, have a wealth of experience in providing the design and installation of heating, ventilation and hot water systems.

Lancaster Passive House has a very energy efficient air source heat pump which can heat the ground floor underfloor heating and bathroom towel rails, when required. Hot water is provided by a Sunamp Thermal Battery, which is heated by the ASHP and the PV panels. A Sunamp stores energy which heats water on demand, unlike a hot water cylinder, which uses energy to heat stored water. This vastly reduces heat loss and therefore saves energy.

A Passive House must have an efficient mechanical ventilation system with heat recovery. There are no trickle vents in the windows of a Passive House and minimal air leakage through the building fabric. 21 degrees were appointed to design the MVHR system. Each habitable room; living area, study and bedroom, must have a supply of filtered fresh air 24 hours a day. The kitchen, utility and bathrooms have extract ventilation, as required by the building regulations. A MVHR system allows the outgoing air to pass by the incoming air to warm it. This saves energy by pre-warming the incoming air, consequently the UFH requires less energy to warm the living spaces.

1. Underfloor heating manifolds (UFH). 2. Heated towel rails. 3. Air Source Heat Pump (ASHP). 4. Sunamp thermal battery. 5. Zehnder ComfoAir (MVHR). 6. GivEnergy Single-Phase Invertor

Lancaster Passive House benefits from a large array of 30 Photovoltaic panels on the south facing roof. Chris Heron from Plugged in Electricians, supplied and installed the PV panels, the single-phase invertor and the batteries, which allows James and Debbie to store electrical power to use later. Excess power can be sold back to the National Grid, which means rather than paying an electricity bill, the PV panels can provide a small income.

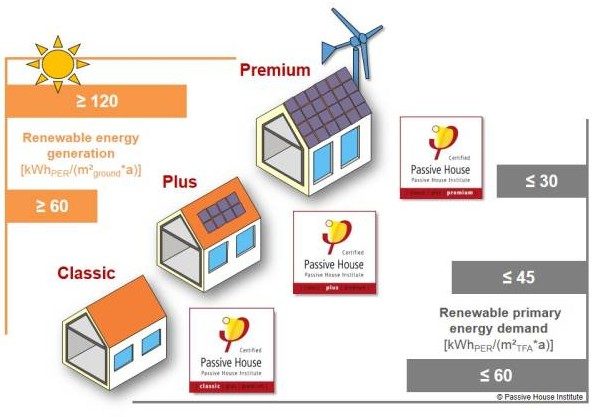

Lancaster Passive House has enough PV panels to generate more than 84 kWhper/(m2.ground.a). It can therefore been certifed as Passive House "Plus".

Passive Houses require very little energy to heat. A building which meets the Passive House "Standard" will require less than 15 kWh/m2a. (that is 15 kilowatt-hours per m2 of floor area, per annum) to heat. If we then add a source of renewable energy to the building, such as solar energy or wind power, we can exceed the energy demand for heating, washing, ventilation, etc.

If the Passive House can generate more than 60 kWhper/(m2.ground.a) it is Passive House "Plus" standard.

If the Passive House can generate more than 120 kWhper/(m2.ground.a) it is Passive House "Premium" standard.

9. In Detail

Ground floor construction: Engineered timber flooring on a levelling screed, on underfloor heating insulation boards, laid on 150mm thick ground bearing concrete slab, on 300mm thick PIR insulation, on a damp proof membrane, on 50mm sand blinding over hardcore.

Floor U-value: 0.077 W/(m2K)

Wall construction: Cedar timber cladding fixed to timber battens on BUILD-A-KIT timber panels. The panels are factory manufactured and include: a breathable membrane on 13mm Panelvent board, 300mm I-beam structural frame filled with Rockwool mineral wool insulation, OSB board and Intello Proclima vapour control layer.

BUILD-A-KIT factory fitted the cladding battens on the outside of the panels and the service void battens on the inside of the panels. The panels are internally lined with Fermacell board, which is a high performance fibre gypsum alternative to plasterboard.

Wall U-value: 0.118 W/(m2K)

Roof construction: The south facing roof is covered by 30 Photovoltaic panels (PV) supplied and fitted by Plugged In Electricians. The panels are Longi Hi Mo X6 Explorer panels.

The PV panel trays sit on timber battens over the roof panels. The panels are factory made by BUILD-A-KIT and include: a breathable membrane over 300mm I-beam structural panels filled with Rockwool mineral wool insulation, OSB board and Intello Proclima airtight vapour control layer.

The airtight vapour control membrane is protected by the service void on the inside. The panels are lined with Fermacell board internally.

Roof U-value: 0.107 W/(m2K)

10. Project details

Client: James and Debbie Glass

Architect: Kirsty McGhie for JMP Architects

Passive House Consultant: Kirsty McGhie

Passive House Certification: Zero Energy

Location: Lancaster

Completion Date: June 2025

Passive House certification: Certified Passive House Plus

Space Heating Demand: 14.10 kWh/(m2a)

Heat Load: 8.79 W/m2

Primary Energy Renewable (PER) generation: 84 kWh/(m2a)

Overheating: 0.0% in PHPP (% of hours > 25C)

Airtightness at 50 Pascals: 0.5 1/h

Airtightness tester: Green Footsteps Ltd.

Building Control services: Stroma Building Control

Principal Designer for Building Regulations: Kirsty McGhie for JMP Architects

Energy Performance Certificate (EPC): 102 A

Energy Assessment provider: Aldrock

Main Contractor: Self build by James Glass with Darren Winning

Timber Frame: Build-A-Kit

Windows and doors: 21 degrees

Openable roof windows: Fakro

Timber cladding: supplied by Prowood Ltd.

Green Roof: Supplied by Paul Gilby of Dammzons Ltd

PV panels: Longi Hi Mo X6 Explorer

Electrical Inverter and battery: GivEnergy

Electrical services: Plugged in Electricians

Heat recovery ventilation: designed by 21 degrees

MVHR unit: Zehnder ComfoAir Q350

Domestic Hot Water system: Sunamp Thermino

Air Source Heat Pump: Samsung Monobloc heat pump

Plumbing services: Phillip Metcalf Ltd Cooling & Heating Services

Wall linings: Fermacell

Wall and roof Airtightness: Pro Clima Intello Plus membrane, supplied by 21 degrees

Kitchen and utility: Maelstrom Kitchens & Bathrooms

Bathrooms: Bathtime Northwest

Fitted wardrobes: Maelstrom Kitchens & Bathrooms

11. Completion

Part of the Certification process includes checking the execution of the construction works on site. Proof of the execution of the works is provided by site photographs, the results of the airtightness test, the ventilation system report, etc. The construction manager, is this case James, is required to sign a "Construction Manager's Declaration".

Once all the criteria has been fullfilled, the Certificate can be issued. The authenticity of the criteria is confirmed by an identification number which is issued to the Certifier by the Passive House Institute.

Through Passive House Certification you can be sure that the stringent quality requirements of the Passive House Standard have been achieved.

Every Certified building will be added to a world map created by the Passive House Institute. This map can be found on the Passive House Database.

UK Passivhaus Certified projects are added to the Passivhaus Trust Projects Map. This map shows the building typology and identifies the Passihaus standard.